Casting Using Dental Stone

Casting Instructions |

Advanced Casting Instructions |

Casting Using Dental Stone |

Casting Using Plastic & Resin |

Customer Reviews of US Products |

Customer Reviews of Overseas Products |

Below I have four reviews of different types of dental stones. Most any product around 8,000 psi and higher will do just fine in the molds. Don't feel that you have to get any of these products listed below. Instead, consider the shipping costs of the material you order and try to get the best deal on shipping that you can.

Buying Dental Stone

In my opinion, dental stones are the absolute best casting materials to use. The dental stones listed here are actually not called "plaster" at all but are known as Dental Stone. Other brand names can sound something like Die-keen or Veri-die or Apex Stone. Usually if it has Die or Stone in the name, it's probably much harder than your regular plaster.

Buying Dental Stone This video explains the difference between plaster and dental stone and also where to buy it. |

|

There are several kinds of dental stone so whatever you buy, always look at the compressive strength measured in psi (pounds per square inch).

- Regular plaster of Paris ranges from 2,000 to 5,000 psi compressive strength and will chip fairly easily.

- Hydrocal is around 6,000 to 8,000 psi and is more durable.

- Flow Stones such as Merlin's Magic are made to flow more easily and are around 12,000 to 14,000 psi.

- Die Stones such as Excalibur and Die-Keen can go as high as 18,000 psi and cure so hard it's almost like a ceramic material.

Plaster.com. They carry Ultimate Drystone with a compression strength of 16,000 psi along with Hydrostone Super X which has a compression strength of 13,000 psi. You can order using their online shopping cart and shipping a 47 pound box seems to be reasonable.

The Plaster Guys have an Ebay store where you can purchase various types of dental stone. They fit as much as they can into a US Postal Service flat rate box to give you the cheapest shipping cost possible. They have may types of dental stones available so be sure to check the compression strength before you order.

Swords of Honor (located in Idaho). They have an online shopping cart and offer several colors of Merlin's Magic dental stone in 5 lb., 10 lb., 25 lb. and 50. lb packaging. They also sell lots of cool swords and historical gear.

Atlantic Dental Supply (material is shipped from Arkansas). They Sell Merlin's Magic dental stone and accept Visa, Mastercard and Paypal and have an online shopping cart. You can call them at (919) 321-0938 -ask for Bethany.

Merlin's Magic Review

Merlin's Magic is a type of flowstone made by a company called Garreco. You can purchase it from several places. Most of these companies drop ship from Garreco (send the order to Garreco who ships it directly to you) which means that all their dental stone is sent from Arkansas using UPS Ground. Shipping may be fairly expensive depending on how far you live from Arkansas.

Merlin's Magic is a type of flowstone made by a company called Garreco. You can purchase it from several places. Most of these companies drop ship from Garreco (send the order to Garreco who ships it directly to you) which means that all their dental stone is sent from Arkansas using UPS Ground. Shipping may be fairly expensive depending on how far you live from Arkansas.

Merlin's Magic comes in white, tan, gray and dark gray. Personally, I would avoid the dark gray. Maybe it's just me but I've found that the dark gray has so much non-soluble pigment in it that tiny micro-bubbles form, kind of like foam that won't go away. I found that the tan or white colors take stain very well when casting the wooden plank and wood shingle pieces.

| 1. | Mixing Merlin's Magic. This video demonstrates how to mix Merlin's Magic and explains how much water and powder to use to fill an average sized mold. |

|

|---|

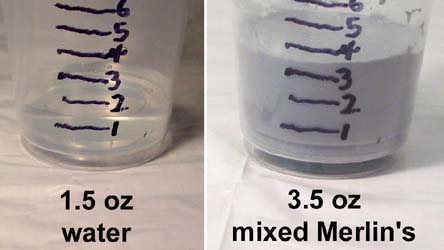

| 2. | For this demonstration, I'm using the Gray Merlin's (not the dark gray). For the average size mold, I'm going to start with 1.5 ounces of water. After mixing the Merlin's, your level should be about at the 3.5 ounce mark. For detailed instructions on the measuring cup you see here and adding the powder to the water, refer to the Basic Casting Instructions page. |

|

|---|

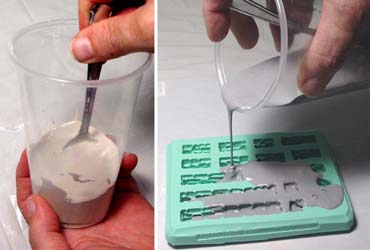

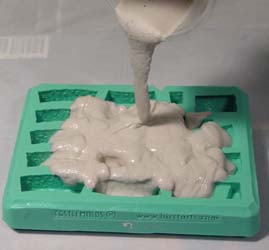

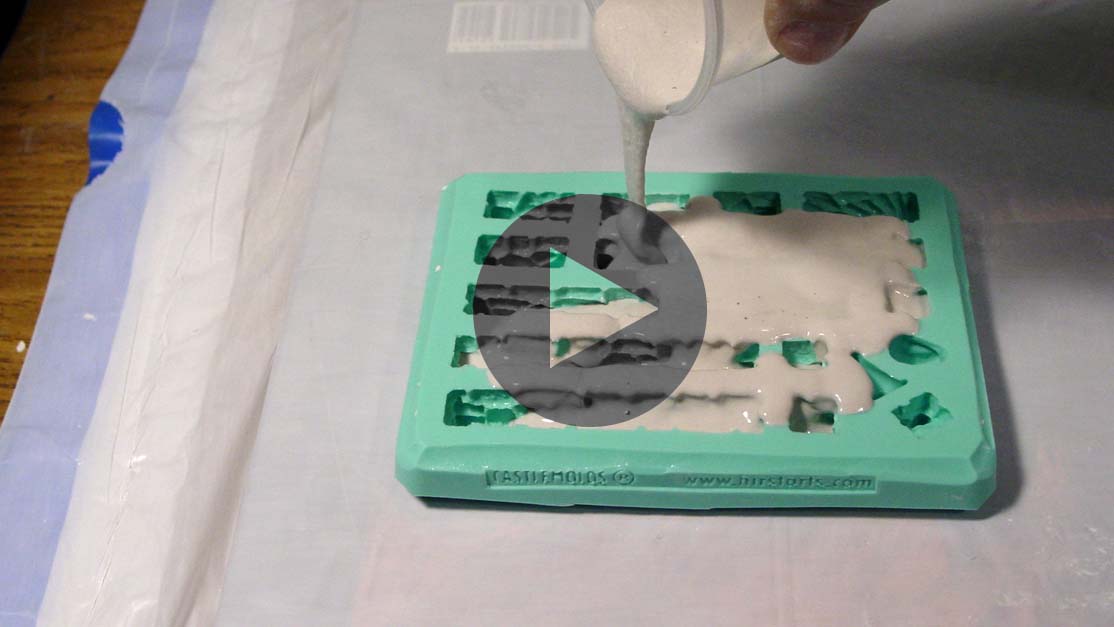

| 3. | Since Merlin's is more of a flowstone, it has an additive that helps the stone stay very liquid, even if you add a lot of powder to the mix. Because of this property, you will notice (if you watch the video above) that Merlin's pours into the mold a lot thinner than the plaster of Paris did. When pouring into the mold, it's better to pour it only the ridges between the blocks rather than directly down into the pockets of the mold. |

|

|---|

| 4. |

You do not have to do this but can scrape it immediately if you like. Because this is a flowstone, the material will start to turn into a liquid again once you start scraping. Sometimes this can cause difficulty when getting the tops of the blocks scraped flat. Imagine filling the mold with water and trying to scrape the top flat. The material sometimes slips under the scraper, or the capillary attraction to the scraper blade can pull away more water than you intend. Because of this, getting the tops of the blocks flat can be challenging. |

|---|

Advantages

|

Disadvantages

|

Excalibur and Die-Keen Review

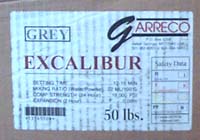

Excalibur is also made by a company called Garraco and can be purchased from the companies listed at the top of this web page. Die-Keen is manufactured by a company called Heraeus Kulzer. These two products are almost identical, both having a compressive strength of 18,000 psi which is the hardest dental stone I have found.

Excalibur is also made by a company called Garraco and can be purchased from the companies listed at the top of this web page. Die-Keen is manufactured by a company called Heraeus Kulzer. These two products are almost identical, both having a compressive strength of 18,000 psi which is the hardest dental stone I have found.

Only the makers of Excalibur have made their product come in the colors of white, tan, gray and dark gray! It doesn't matter which color you pick, they all have the same properties. I found that the tan or white colors take stain very well for the wooden plank and wood shingle pieces. I have had a little trouble with tiny air bubbles (almost foam-like) when casting the dark gray but have not found this with any of the other colors.

Both of these products are widely used by the dental industry and are fairly well known so you will find a lot more suppliers for these materials than you will for Merlin's. However, many suppliers only sell to dentists so you may have to look around for those who will sell to anyone.

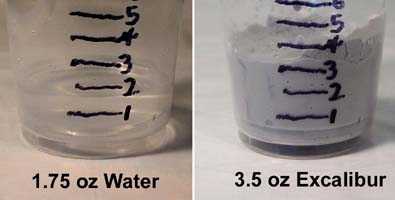

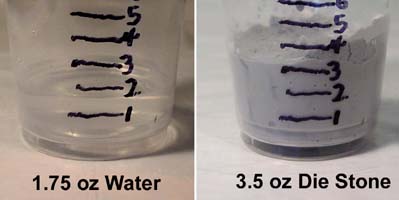

| 2. | For this demonstration, I'm using White Excalibur, although it doesn't look very white in the photo. For the average size mold, I'm going to start with 1.75 ounces of water. After mixing the Excalibur, your level should be about at the 3.5 ounce mark. For detailed instructions on the measuring cup you see here and adding the powder to the water, refer to the Basic Casting Instructions page. |

|

|---|

| 3. | Excalibur is not as much of a flowstone but it does have some additives to help if flow well. I notice that it pours into the mold a little more thickly than Merlin's but a lot thinner than regular plaster of Paris. Since this material is the highest strength available (18,000 psi compression strength), you can mix it a little thin and it will still be quite strong. When pouring into the mold, it's better to pour it only the ridges between the blocks rather than directly down into the pockets of the mold. |

|

|---|

| 4. |

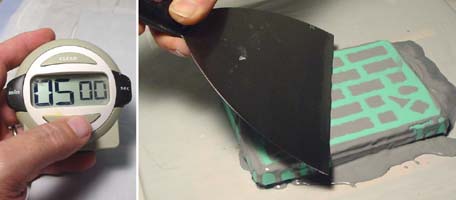

For Excalibur, I think it's better to let the material sit in the mold because you will notice a layer of water on top after sitting. This is because the powder will continue to sink down into the mold before it sets up. If you scrape immediately after pouring, the layer of water will come to the top and your blocks will be slightly short. For this reason I don't suggest using the glass method with Excalibur. Lightly scrape off this layer of water, then go ahead and scrape off the surface of the mold. I have found that I can get a flatter scrape across the top of the mold than with using Merlin's because this material doesn't flow as much when scraping. |

|---|

Advantages

|

Disadvantages

|

Die Stone Review

Die Stone is a generic name for a family of dental stones. This particular die stone has a compressive strength of 14,000 psi and is made by a company called The Plaster Guys.

Die Stone is a generic name for a family of dental stones. This particular die stone has a compressive strength of 14,000 psi and is made by a company called The Plaster Guys.

If for some reason the above link does not work, you may still find them by going to Ebay and doing a search for "plaster guys".

One of the great things about this company is they try to save you money on shipping by taking advantage of the flat rate boxes from the United States Postal Service. The largest box you can purchase from them is a 38 pound box, but that's because they simply cannot fit any more material into a flat-rate mailing box.

One of the great things about this company is they try to save you money on shipping by taking advantage of the flat rate boxes from the United States Postal Service. The largest box you can purchase from them is a 38 pound box, but that's because they simply cannot fit any more material into a flat-rate mailing box.

They currently list their shipping as free but they simply figure the shipping cost into the cost of the material itself. When looking at prices, always add the shipping cost when comparing products.

| 1. | Mixing Die Stone. This video demonstrates how to mix Die Stone and explains how much water and powder to use to fill an average sized mold. |

|

|---|

| 2. | For the average size mold, I'm going to start with 1.75 ounces of water. After adding the die stone powder to the water, your level should be about at the 3.5 ounce mark after mixing. For detailed instructions on the measuring cup you see here and adding the powder to the water, refer to the Basic Casting Instructions page. |

|

|---|

| 3. | This material is not a flow stone. In other words, when pouring it acts like plaster of Paris. However, this material is 14,000 psi compressive strength which is about four times stronger than plaster of Paris. This means you can mix this material thinner than you normally would and still end up with very strong blocks. In my opinion if you have a lot of tiny, deep detailed pieces to cast then you should really use a vibrating table for the best results. |

|

|---|

| 4. |

After it thickens up slightly, I found that this material is almost perfect for scraping the top of the mold clean and flat. While mixing and scraping, I found this material to be slightly more coarse than Excalibur but I still ended up with perfect castings. |

|---|

Advantages

|

Disadvantages

|

Flow Stone Review

Flow Stone is a generic name for a type of dental stone. This particular flow stone is also sold by The Plaster Guys, who also sells the die stone mentioned in the article above.

Flow Stone is a generic name for a type of dental stone. This particular flow stone is also sold by The Plaster Guys, who also sells the die stone mentioned in the article above.

This product has an additive that gives it thixotropic properties, so it will flow into the mold easier. This product does flow better than most dental stones but not as good as Merlin's. It also has a 9,000 psi compressive strength which is a lower compressive strength than the other products shown here. However, this is still three times stronger than many plasters available.

| 1. | Mixing Flow Stone This video demonstrates how to mix Die Stone and explains how much water and powder to use to fill an average sized mold. |

|

|---|

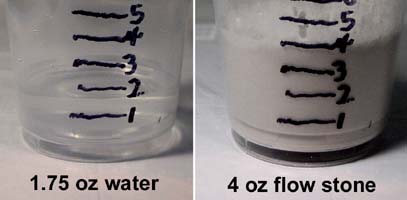

| 2. | For the average size mold, I'm going to start with 1.75 ounces of water. After adding the die stone powder to the water, your level should be about at the 4 ounce mark after mixing. For detailed instructions on the measuring cup you see here and adding the powder to the water, refer to the Basic Casting Instructions page. |

|

|---|

| 3. | I found this material to flow into the mold fairly well but not quite as good as the Merlin's. It also had a slightly more grainy texture to it, as if the powder was not ground as fine as the Merlin's or the Excalibur. However, it did pour into the mold just fine and release air bubbles better than the die stone shown above. You should be able to get good detail on difficult molds without a vibrating table, as long as you use a pound board of some kind as shown in the video. |

|

|---|

| 4. |

However, you can scrape the mold immediately if you like. I found that this material scrapes a little easier than the Merlin's when trying to get the bottoms flat. |

|---|

Advantages

|

Disadvantages

|

I like to let the material set in the mold for 5 minutes before scraping to let the material thicken up slightly.

I like to let the material set in the mold for 5 minutes before scraping to let the material thicken up slightly.

I like to let the material set in the mold for 10 minutes before scraping.

I like to let the material set in the mold for 10 minutes before scraping.

If you let the material set in the mold for 5 minutes before scraping, the material will thicken up slightly to the consistency of soft margarine.

If you let the material set in the mold for 5 minutes before scraping, the material will thicken up slightly to the consistency of soft margarine.

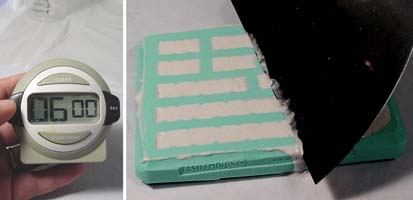

If you let the material set in the mold for 6 minutes before scraping, the material thicken up slightly and will be easier to get the bottom of the blocks flat.

If you let the material set in the mold for 6 minutes before scraping, the material thicken up slightly and will be easier to get the bottom of the blocks flat.